Wind Farm Facts

Strong Figures

40

Wind Turbines

200

Megawatts

200.000

Households

800

Million kWh/year

Facts

| Location Southern German Bight, north of 54º latitude |

| Distance from the coast 45 km off the island of Borkum |

| Water depth 25–35 m |

| Number of wind turbines 40 |

| Installed power 200 MW |

| Power generation per year 800 GWh |

| Full utilisation hours 3,500––4,000 per year |

| Required space 56 km2 |

| Operation time limit 25 years |

| Start of construction Summer 2011 (building decision on 15-12-2010) |

| Beginning of continuous operation Autumn 2015 |

| Shareholders 29 |

Technical Data

| Type of wind turbine (WTG) Adwen AD5-116 (formerly Areva Wind M5000) |

| Net power 5 MW |

| Total height from waterline 148 m |

| Total height from sea bottom 178 m |

| Hub height 90 m |

| Rotor diameter 116 m |

| Total weight > 1000 t |

| Rotor weight 110 t |

| Nacelle mass 200 t |

| Foundation structure Tripod |

| Tripod height 45 m |

| Piles length (Tripod) 35-45 m |

Operational Data

| Rated power 5 MW |

| Switch-on wind speed 3.5 m/s (wind force 3) |

| Nominal wind speed 12.5 m/s (wind force 6) |

| Shutdown wind speed 25 m/s (wind force 10) |

| Speed 5.9–14.8 rpm |

| Blade tip speed 90 m/s (324 km/h) |

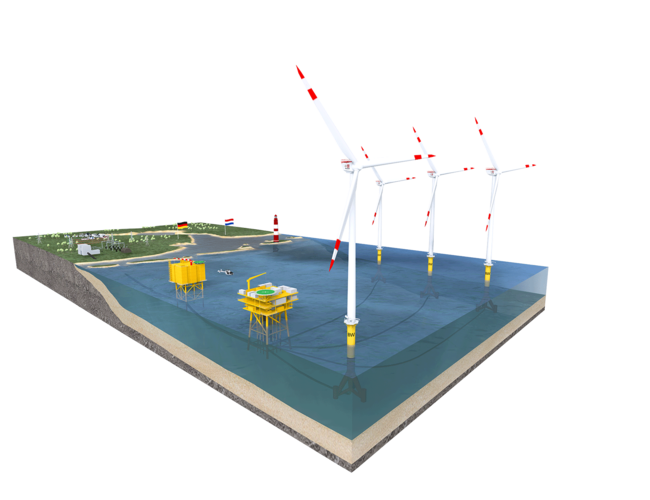

The firm anchorage on the seabed

Tripod

The tripods anchor the wind turbines firmly to the seabed. The steel structures, which weigh up to 900 t and are up to 50 m high, were “nailed” to the seabed using 30–40 m long steel pipes with a diameter of around 3 m, known as piles. In a process called prepiling, the steel pipes weighing up to 100 t were first placed exactly at the appropriate points on the seabed using a pile-driving template, and each pile was driven into place with up to 3,000 hammer blows. The tripods were then placed on the steel nails with millimetre precision. A total of around 48,000 t of steel were used for the wind farm’s foundation, consisting of 40 tripods and 120 steel nails.

Trianel Wind Farm Borkum

40 Wind Turbines

Trianel Wind Farm Borkum consists of 40 Areva M5000 wind turbines with a total capacity of 200 MW. Each wind turbine has an output of 5,000 kW. The wind turbines with a total height of 148 m from the waterline to the blade tip consist of a nacelle, the rotor star and the tower. Calculated from the seabed, the turbine is just under 178 m high and thus taller than Cologne Cathedral (157 m).

At a height of 90 m above sea level, the nacelle, which weighs around 200 t and covers an area of about 88 sqm, houses the main technical equipment for energy conversion: the gearbox, the rotor bearing and the generator.

The rotor star has a total diameter of 116 m and thus covers an area of about one and a half soccer fields. As the rotor star rotates, the energy of the wind is first converted into mechanical energy and then into electrical energy in the generator. The wind turbines are designed for wind speeds of up to 25 m/s, which corresponds to wind force 10. At full power, the rotors rotate around their own axis around 15 times a minute at a blade tip speed of around 320 km/h.

The "socket" of the wind farm

The Trianel

Substation

The wind farm’s internal substation is its “socket”. The substation, which is located 20 m above sea level on two decks, houses two large transformers. These convert the electricity produced from the 33 kV voltage level to the 155 kV voltage required for transmission to the grid. Trianel Wind Farm Borkum shares the substation with its sister wind farm Trianel Wind Farm Borkum II.

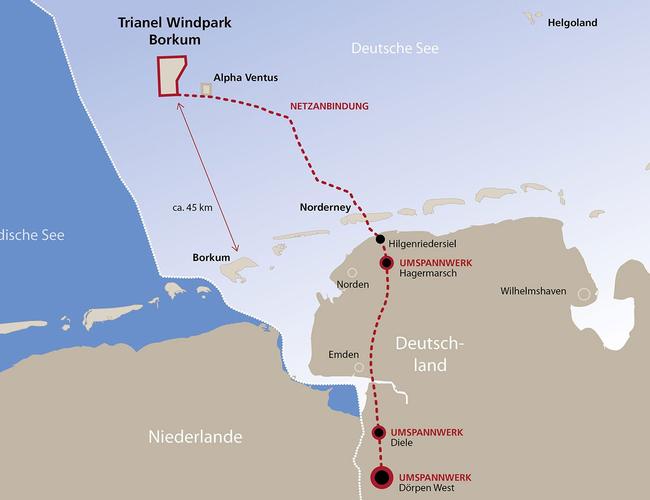

The Transport

Grid Connection (TENNET)

The DolWin alpha converter platform with a capacity of 800 MW is the heart of the grid operator TenneT’s offshore grid connection DolWin 1. With a height of 42 m and a footprint of around 2,600 sqm, it has an impressive size. Here, the three-phase current produced at the Trianel Wind Farm Borkum is converted into direct current and then transported onshore via a 75 km long submarine cable. The wind power reaches the Dörpen West converter station via a further 90 km long land route.

The conversion

Converter Station

Dörpen West

At the Dörpen West converter station in Emsland, the direct current from the grid connection in the North Sea is converted back into three-phase current and finally fed into the transmission grid. In this way, the climate-friendly produced electricity reaches the consumers.